Vendor-managed inventory (VMI) is an inventory management practice in which a supplier of goods, usually the manufacturer, is responsible for optimizing the inventory held by a distributor.

It is a continuous replenishment program in which the retailer provides the supplier with the detailed information to allow the supplier to manage and replenish product at the store or warehouse level which carries several benefits like solidified customer vendor relationship, reduced shipping cost and lead time, less human errors and improved service levels. Thus, the vendor is responsible for the retailer’s ordering cost, while the retailer has to pay for their own holding cost.

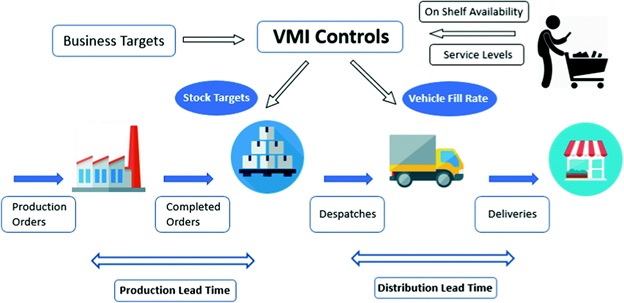

A two stage VMI supply chain will look like

Source https://link.springer.com/chapter/10.1007/978-3-030-01614-2_13

As replenishment frequencies play an important role in integrated inventory models to reduce the total cost of supply chains which many studies fail to model it in mathematical problems, VMI can really help in managing those tough times. As a symbiotic relationship, VMI makes it less likely that a business will unintentionally become out of stock of a good and reduces inventory in the supply chain. Furthermore, vendor (supplier) representatives in a store benefit the vendor by ensuring the product is properly displayed and store staff are familiar with the features of the product line, all these while helping to clean and organize their product lines for the store. VMI can also decrease the magnitude of the bullwhip effect. Using this technique Vendors benefit from more control of displays and more customer contact for their employees; retailers benefit from reduced risk, better store staff knowledge (which builds brand loyalty for both the vendor and the retailer), and reduced display maintenance outlays. Consumers benefit from knowledgeable store staff who are in frequent and familiar contact with manufacturer (vendor) representatives when parts or service are required. Store staff have good knowledge of most product lines offered by the entire range of vendors. They can help the consumer choose from competing products for items most suited to them and offer service support being offered by the store.

At the goods’ manufacturing level, VMI helps prevent overflowing warehouses or shortages, as well as costly labor, purchasing and accounting. With VMI, businesses maintain a proper inventory, and optimized inventory leads to easy access and fast processing with reduced labor costs.

Some of the biggest companies known to use VMI are:

- Walmart

- Home Depot

- Bosch

- Amazon

- Procter & Gamble

Here are the 4 Steps to VMI Implementation in businesses:

- Get to Know Each Other. The first step of starting a VMI program is to take the vendor-customer relationship to another level of trust and understanding.

- Get Organized.

- Prepare Inventory Data.

- Set Targets and Adopt an Order Process.

Adopting RFID technology in vendor managed inventory (VMI) increases inventory efficiency and decreases the amount of capital tied to stock. Radio-frequency identification (RFID) uses wireless electromagnetic fields to transmit data, generally used for the purposes of identifying and tracking tags attached to objects. The tags contain electronically stored information Storage data is transmitted in real time RFID technology provides stocks in the VMI model with real-time transparency. A study conducted by the University of Arkansas RFID Research Center on Walmart’s use of RFID revealed that stores that incorporated RFID reduced out of stocks at store level by 16% over non-RFID locations. the most modern and effective organizations are using RFID technology to automate assets tracking. Systems based on RFID solutions avoid many problems caused by manual tracking.

Though there are multiple advantages using VMI, we also need to note the challenges faced while using VMI which are:

- Loss of control. Giving over access to your data to a third party can be uncomfortable for some businesses

- Limited options. Once companies go with a VMI partner, it may cause a big disruption to that supply chain and become unsatisfied with their service at times

- Less agile market responsiveness

To conclude, a vendor-managed inventory solution links the entire supply chain, effectively giving the manufacturer, at one end of the chain, direct visibility into the retailer’s sales data, at the other end. With actual customer sales data, manufacturers are able to more accurately predict how much product to manufacture and it always helps across many tough times specially during such pandemic situations.

– Dr. Karpagavalli.G